We Deliver all products Australia Wide

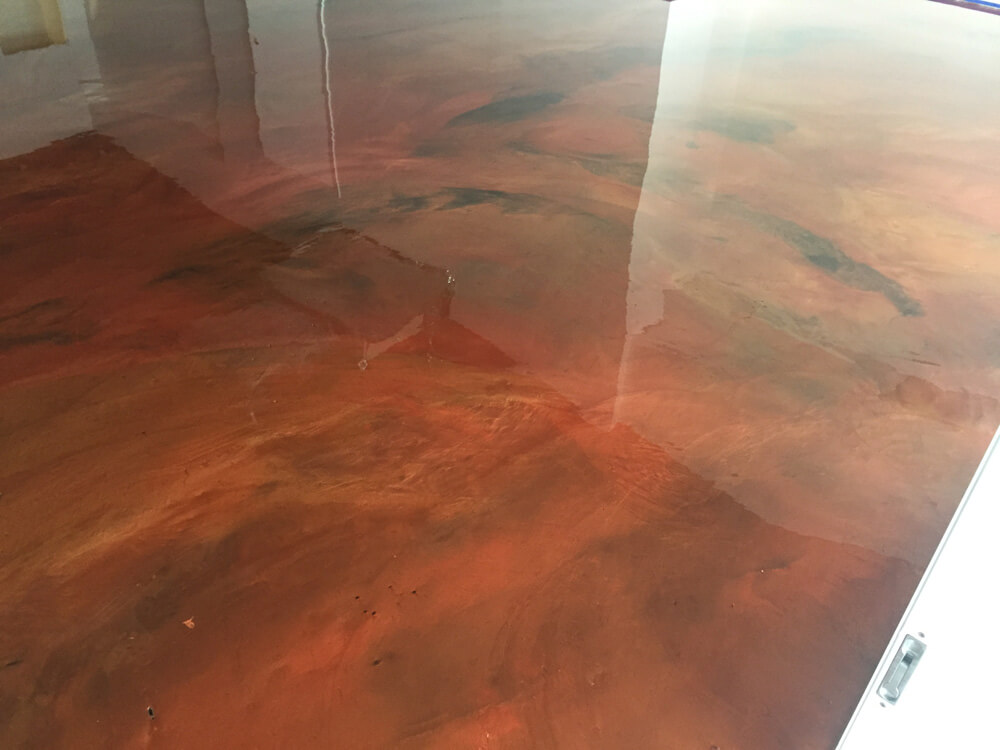

Metallic Epoxy Flooring

Con-Treat supply the full range of products and equipment to complete your Metallic Epoxy Floor from the beginning of the project through to the final finished floor. We offer the right advice and full back up support, whether you are doing a DIY or you are a trade professional. Call Con-Treat today on 1300 044 625 to order your Metallic Epoxy Supplies.

Metallic Illusion is a three-dimensional Metallic Epoxy Flooring system designed to create elegant and exotic looking seamless floors. Ideal for residential use, retail stores, office spaces, lobby areas, tattoo parlors, barber shops, hair salons, restaurants, clothing stores, casinos and showroom floors.

Metallic Illusion is a high gloss, 100% solids, low viscosity, solvent free polymer system integrating the latest technology. Metallic Illusion combines the ease of application of epoxies with the toughness and wear resistance of acrylics. It offers a safe alternative to conventional solvent based materials as well as being resistant to ultra violet degradation for internal behind window applications.

The Metallic Epoxy Flooring system consists of:

- SurePrime

- SureFloor HS (Base Coat)

- SureFloor Clear Epoxy

- Metallic Pigments (Add to Clear Epoxy)

- Fortis 519 Polyurethane (Top Coat)

*Hints:

- To extend working times, get the epoxy out of the mixing bucket as quickly as possible by putting a “ribbon” on the floor straight away.

- Never mix a new batch of epoxy floor coating in the previous bucket as this will dramatically reduce the pot life. Use fresh buckets with each batch.

- When re-coating epoxy, it is always advisable to do a 50/50 Methylated Spirits/Water wash prior to sanding. This will remove the possibility of any amine residue sitting on the surface, especially during low temperature applications.

- Only mix enough epoxy to work with for about 10-15 mins at a time.

What is the final thickness of the Metallic Illusion?

When applied at approx 1m2 per ltr, then the final finish will be 1mm.

Do you need to seal a metallic epoxy floor?

It is not absolutely necessary to use another sealer over the top of the metallic floor, however it is advisable. The use of a UV stable polyurethane (Fortis 519) will protect the epoxy from scratching and also provide UV protection.

How do you prepare the metallic epoxy for sealing with a polyurethane?

The epoxy must be left to fully cure. Once cured, it is strongly recommend to wash the floor with a 50/50 mix of methylated spirits and water to remove any amine residue the epoxy may have left on the surface. It will then need to be sanded with a fine grade screenback and then vacuumed thoroughly.

Send an enquiry

Fill in the form below and one of our team members will get back to you within 1 business day.